EXPOL AND THE ENVIRONMENT

At EXPOL caring for the environment has always been an important part of our philosophy.

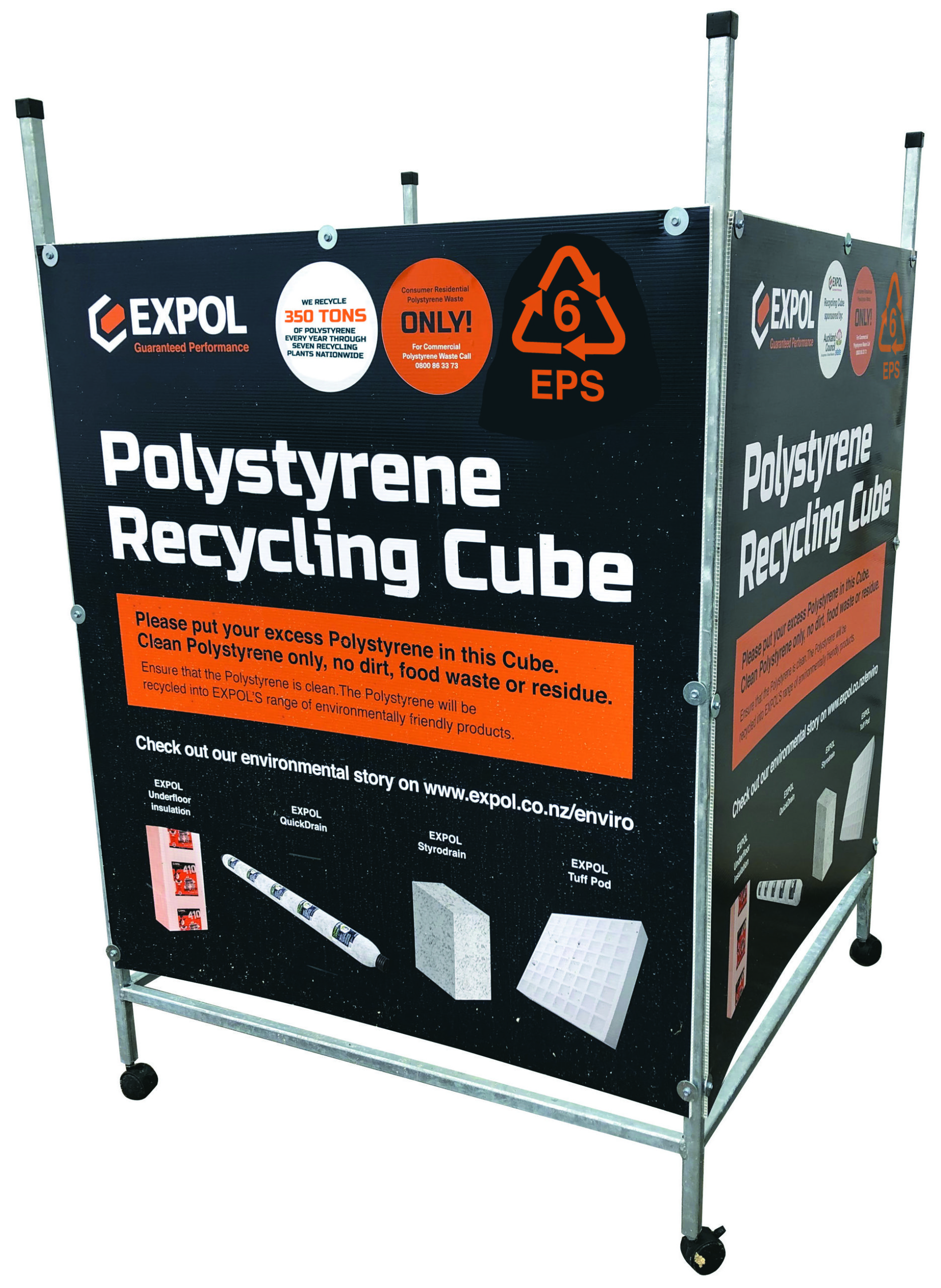

We have invested in and operate seven manufacturing facilities nationwide all of which include a polystyrene recycling plant.

Expanded Polystyrene offers exceptional eco-credentials and is therefore ideally suited to new generation eco-friendly building projects.

All of our manufacturing processes comply with the latest environmental regulations. Polystyrene is chemically and environmentally non-aggressive and it can be recycled into long-life products. We invite you to view the video opposite to see the EXPOL Recycling journey.

THE CIRCULAR ECONOMY

At EXPOL we’ve made a commitment to the environment and take responsible manufacturing seriously. We are focused on a true closed-loop recycling process – 75% of the products (by volume) we make use recycled content, and we have plans and concepts in place to do even better.

![]()

Hence the introduction of our EXPOL Earth resource centre and brand which is designed to incorporate all our environmental and sustainability policies and initiatives. Look out on our packaging for the EXPOL Earth brand which indicates that the product contains recycled content or can be recycled by EXPOL. Click here to visit the EXPOL Earth resource centre.

EXPOL ECO CREDENTIALS

EXPOL insulation products are made in New Zealand, using an environmentally responsible manufacturing process and are 100% recyclable.

98% of EXPOL insulation product is actually trapped air. As well as ensuring excellent thermal insulation properties this means the amount of EPS material required is minimal.

![]()

PROMOTING HEALTHY, ENERGY EFFICIENT HOMES

EXPOL insulation products are designed to create warm, dry, healthy environments with reduced heating requirements.

They are proven to deliver insulation R-values that meet or exceed Building Code requirements and enable homes to achieve Green Star rating credentials.

EXPOL insulation products are rigid, so they won’t sag or slump and will retain their original R-values over time.

PROTECTING NEW ZEALAND’S ENVIRONMENT

As a New Zealand owned company, EXPOL is committed to protecting our natural environment. The manufacturing of polystyrene insulation does not create CFCs or HCFCs.

Our Expanded Polystyrene products are totally recyclable and we have seven Expanded Recycling Plants situated at our manufacturing facilities in Auckland, Tauranga, Wellington, Blenheim, Christchurch (Rolleston & Belfast) and Cromwell. This ensures that all waste product can be re-used.

COMMITTED TO INDUSTRY BEST PRACTICE

EXPOL is a long-standing member of the leading industry associations.

Plastics New Zealand is the country’s leading industry association for plastics, who aim to advance plastics-based technologies in an sustainable manner.

Asian Manufacturers of Expanded Polystyrene (AMEPS).

AMEPS supports and promotes the recycling of EPS products and our membership gives EXPOL access to the latest advances in the field.

Our zero waste factories recycle 400 tons of polystyrene a year. That’s 3200 cubic metres a month.

An important component of our product development and manufacturing is our commitment to closed manufacturing.

Polystyrene is highly re-useable and at EXPOL we recycle it into products including EXPOL UnderFloor Insulation, EXPOL Tuff Pods, EXPOL StyroDrain and EXPOL QuickDrain to name just a few.

SUSTAINABILITY CREDENTIALS

EXPOL is a long-standing member of the leading industry associations Plastics NZ (EPS NZ Sector), EPSA (EPS Australia) and the Asian Manufacturers of Expanded Polystyrene (AMEPS).

These organisations support and promote the recycling of Expanded Polystyrene products and our membership gives EXPOL access to the latest advances in the field.

Sustainability Manager

We have recently appointed Cameron Brooks our Sustainability Manager. Cameron is responsible for and our sustainability practices both externally and internally. Should you require any further information on our environmental and sustainability initiatives please email cameron.brooks@expol.co.nz